Innovative sludge treatment and resource recoveryfor sustainable steel production (ISTRESS)

The ISTRESS project aims to address the challenges faced by the stainless steel industry in managing metal hydroxide sludge, a byproduct typically landfilled, causing environmental and economic issues. By developing an advanced, scalable solution to recover valuable metals such as nickel, chromium, and molybdenum, the project seeks to reduce reliance on virgin raw materials and minimize environmental impact.

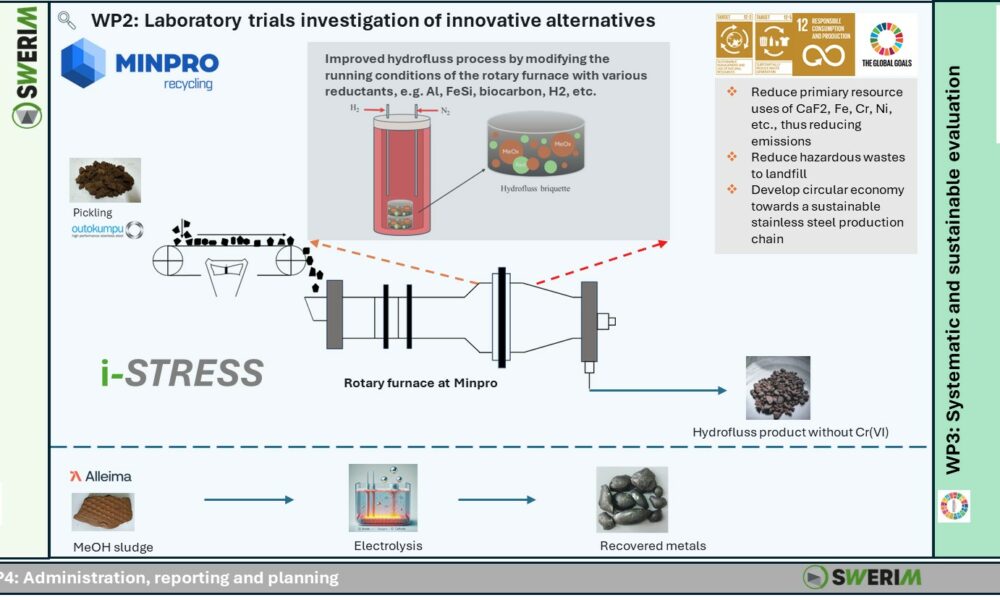

Electrowinning will play a central role in extracting high-purity metals, while metal reduction using FeSi, aluminum, biocarbon, etc. will enhance recovery from various sludge compositions. Additionally, the project aims to reduce the formation of Cr(VI) by modifying kiln atmospheres with nitrogen-based reducing environments.

The project will focus on laboratory trials to validate and optimize these methods, paving the way for a technically and economically viable solution. In the long term, the goal is to scale the process for industrial application, resulting in reduced landfill waste, improved resource efficiency, and decreased environmental impact. The ISTRESS project aligns with Sweden’s sustainability goals and has the potential to set new benchmarks in waste management and metal recovery on a global scale.