ReLignin: Sustainable Additive Manufacturing with RecycledLignin

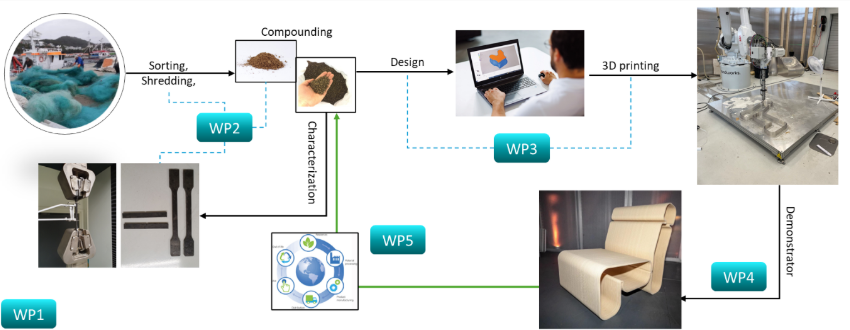

The ReLignin project aims to address some significant environmental challenges by creating a circular and sustainable production system as traditional manufacturing processes have a significant carbon footprint. The ReLignin project utilises additive manufacturing (AM) technologies to create products with a lower environmental impact by reducing waste while using renewable resources. ReLignin increases the recycling of polymer waste materials into secondary raw materials for AM and ensures the circularity of recycled polymer waste composites through repelletisation for further AM.

Lignin, often seen as a residual product from the paper and biofuel industry, can be effectively utilised to significantly increase resource efficiency and reduce environmental pollution. By developing a sustainable material system with lignin, we can reduce our dependence on petroleum-based plastics, which are both resource-intensive and non-renewable. The project aims to blend a bio-based material from Swedish forest residues, a secondary raw material that does not compete with food, which is well mixed with recycled polymers to deliver Net-Zero plastics.