Circular Sub-Sea Infrastructure: Enabling Low-Carbon Welding and Repair (CIRCWELD)

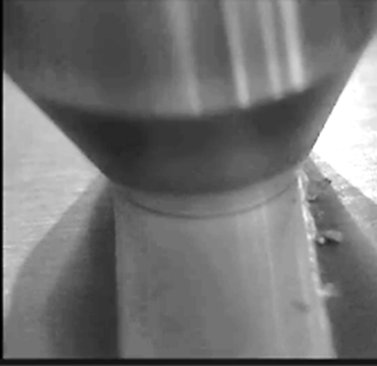

CIRCWELD pioneers the use of Friction Stir Welding (FSW) to transform the lifecycle of sub-sea high-voltage cable, which are critical components of offshore renewable energy systems and other infrastructures. Current welding and repair practices rely on replacing long sections of damaged cable, which is costly, resource-intensive, and emissions-heavy. FSW offers a solid-state alternative that reduces welding energy use by up to 80%, eliminates filler materials, and enables modular, in-situ, and robotic repair. This project will validate FSW on aluminum, copper, and bi-metallic conductors, assess its feasibility for underwater deployment, and perform lifecycle and economic analyses. Outcomes will include validated weld performance data, circular cable joint designs, and a roadmap for industrial adoption, establishing Sweden as a leader in sustainable, resilient offshore infrastructure aligned with EU net-zero targets.