GREEN-SAW: Tools to Generate Resource and Energy Efficient Next-gen Sawmills

GREEN-SAW aims to create next-generation resource- and energy-efficient cutting tools for sawmills, radically reducing sawdust generation and increasing the yield of high-value wood products. Today, 10–15% of log volume becomes low-value sawdust, often from the most valuable parts — resulting in significant raw-material losses and unnecessary CO₂ emissions.

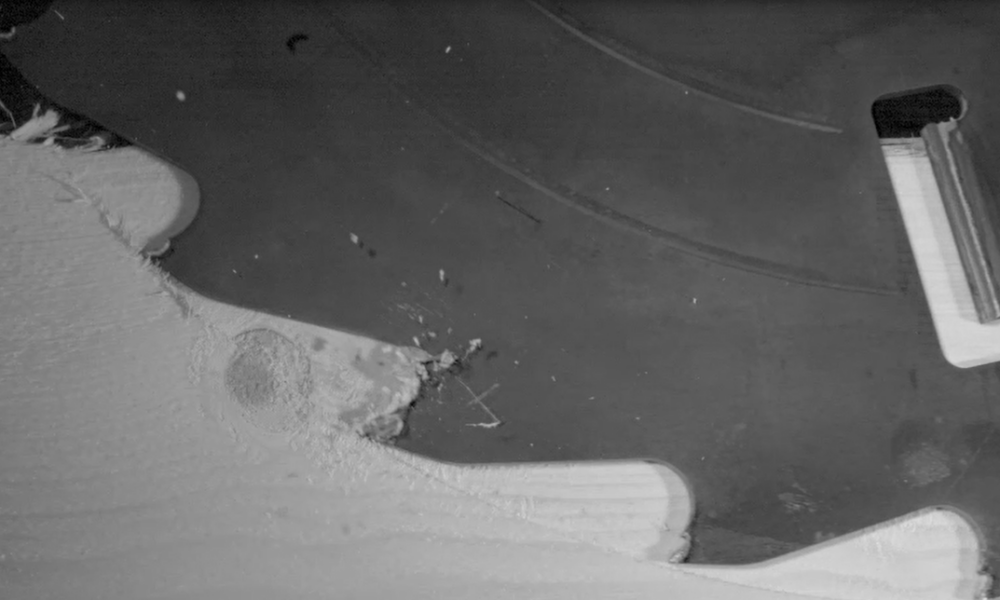

By combining CT scanning, high-resolution measurement techniques, and models for cutting forces and chip formation, GREEN-SAW develops tools tailored to today’s high-speed sawing processes. Reducing saw-kerf width by just 1 mm in Swedish sawmills can generate SEK 2.5 billion per year in added value, increase long-term CO₂ storage in wood products by 500,000 m³, and lower annual emissions by up to 200,000 tonnes.

The project brings together LTU, RISE, leading sawmills, and tool manufacturers to develop predictive models, industrial prototypes, and new thin, stable sawing tools. GREEN-SAW thus lays the foundation for the sawmill processes of the future, delivering higher yield, lower energy use, improved product quality, and strengthened competitiveness within the Swedish wood industry.