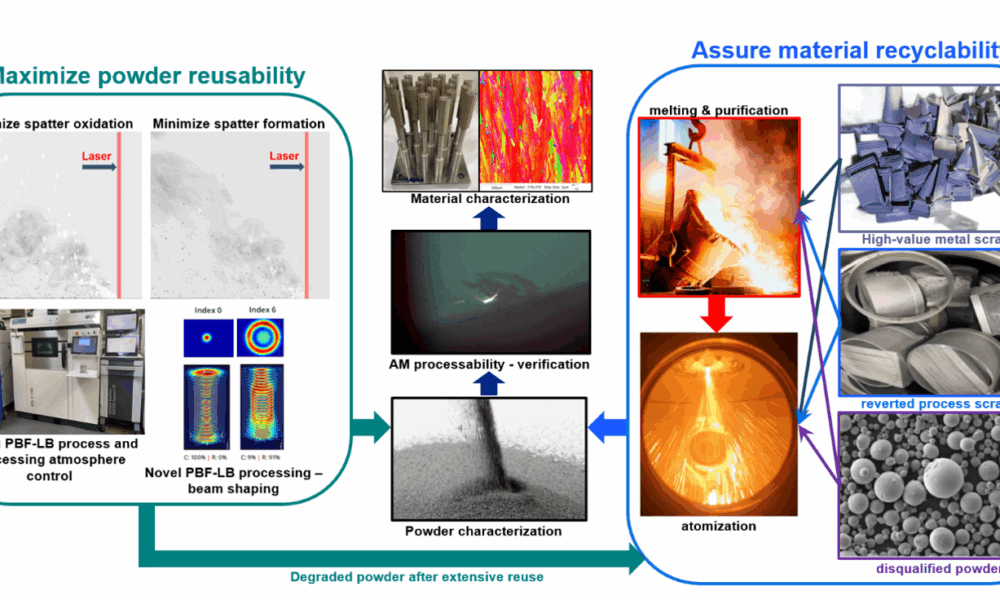

Scrap to Metal Powder: Circular Metal Additive Manufacturing for Increased Resource Efficiency and Resilience

Additive manufacturing (AM) is considered as one of the most sustainable manufacturing processes thanks to near-net shape manufacturing and full material utilization. In comparison to subtractive manufacturing processes, material in metal AM is only used where needed and thus allows to significantly reduce material waste, assuming that powder can be fully reused and amount of material loss during AM processing is negligible and amount of supports is minimized to minimum/avoided. However, considering the low maturity of AM technology, AM is not as green and sustainable as it could be as there is still a big potential for maximizing material reuse as well as finding ways for recycling disqualified powder. During powder bed AM processing, typically 20 to 40% of the powder feedstock is used to build components. Hence, 60 to 80% of the powder feedstock should be reused after each manufacturing cycle. However, the quality degradation during each production cycle requires a regular replacement with virgin powder when necessary. Hence, typically powder feedstock is not reused more than ten times, often much less, resulting in expensive process waste, especially in the case of highly alloyed materials. SCARLETT is aiming to increase resource efficiency of powder-based metal AM through: i) significantly decreasing powder degradation using recent advanced in PBF-LB processing (laser shaping) and AM process control (control of oxygen content and optimized process gas solutions); ii) the optimization of AM waste streams (used powder, printed support structures, after-life and failed components), enabling transition from a linear to a circular economy for AM. Hence, by transforming metal waste into high-value metal powder for AM, SCARLETT will further increase sustainability of metal AM, increase resilience and reduce the need for extraction of natural resources.